-228x228.png)

-228x228.png)

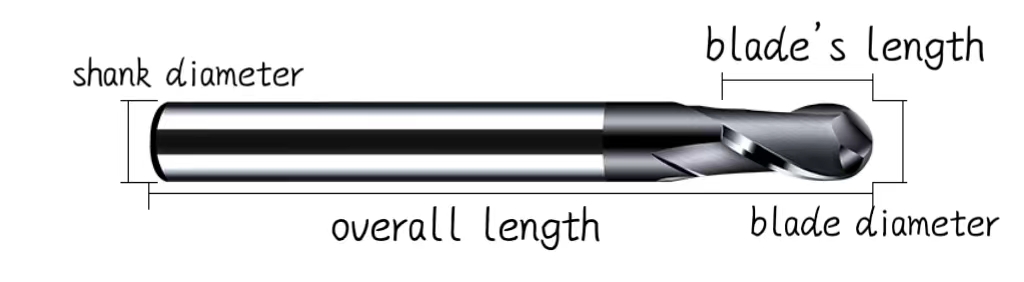

HRC55° Black coated ball knife

$2.00

- Ex Tax: $0.00

- Price in reward points: 400

- Product Code: HRC

- Reward Points: 300

- Category:

Raw material: ultra-fine grain imported tungsten steel;

Coating: high aluminum titanium;

Applicable processing materials: HRC30~55 hard die steel, carbon steel, cast iron, tool steel, copper alloy, alloy steel, stainless steel, titanium alloy, etc.

Processing cooling conditions: cutting liquid cooling/air cooling;

Features: good rigidity, high wear resistance, high machining precision

Product Characteristics

● Fine tungsten carbide base metal with high toughness, covered with high aluminum-titanium coating, abrasion resistance;

● Large capacity chip removal, not easy to stick knife to achieve high efficiency processing, workpiece accuracy and finish better;

● Dedicated to CNC milling machine high-speed cutting pin, can increase smoothness, reduce wear coefficient, reduce tool change times, improve machine efficiency, save workpiece making time;

● Balanced cutting force, eliminating uneven feed, more conducive to processing; Non-calibration accuracy up to 0.002mm.

Product Parameters

| Memory | |

| test 1 | 16GB |

| Processor | |

| No. of Cores | 4 |

-200x200.png)