-228x228.png)

-228x228.png)

HRC65° lengthened blue ball knife

$0.00

- Ex Tax: $0.00

- Product Code: HRC

- Category:

Raw material: ultra-fine grain imported tungsten steel;

Coating: NACO nano coating

Applicable processing materials: HRC30~65° die steel, carbon steel, cast iron, tool steel, copper alloy, alloy steel, stainless steel, titanium alloy, etc.

Processing cooling conditions: cutting liquid cooling/air cooling;

Features: good rigidity, high wear resistance, high machining accuracy; ,

Product Characteristics

1. Fine grained tungsten carbide base metal has high toughness, is covered with NACO nano coating, and is abrasion resistant.

2. Large capacity chip removal, chip removal fast, not easy to stick knife to achieve high efficiency processing, high precision and gloss of the workpiece.

3. Dedicated to CNC milling machine high-speed cutting pin, can increase smoothness, reduce wear coefficient, reduce tool change times, improve machine efficiency, save workpiece making time.

4. Balanced cutting force, eliminating uneven feed, more conducive to processing.

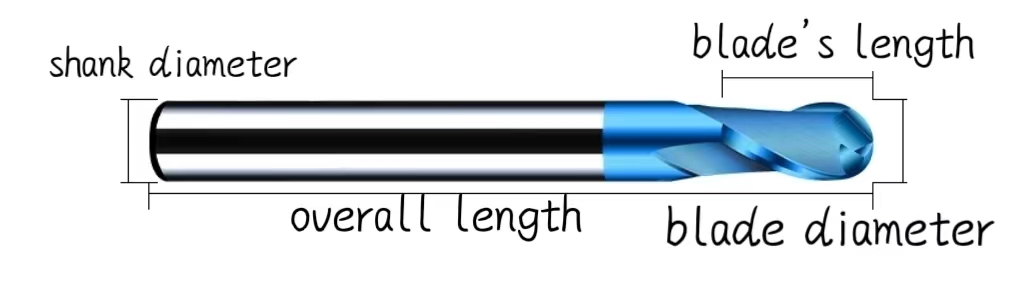

Product Parameters